Rumored Buzz on Durma Fiber Laser

The kind of laser cutting employed in the ceramic industry is typically CO2 laser cutting, which utilizes a high-powered laser to puncture the material. This kind of laser cutting is exact and also can create extremely complicated styles. CO2 laser cutting is also fairly quick, making it excellent for usage in the ceramic production procedure.

Silicon manufacturing refers to the production of silicon wafersthin discs of semiconductor product that are made use of in the manufacture of numerous electronic gadgets. The kind of laser cutting used in this industry is called CO2 laser cutting. It is utilized to create the small-scale functions discovered on silicon wafers.

All about Durma Press Brakes Toronto

These items can be made use of in a variety of markets, such as building, vehicle, and aerospace. These products can be utilized for building, furnishings production, or other purposes.

This type of laser makes use of a beam of infrared light to reduce with wood. Figure 1 is an instance of laser cutting with wood:.

The Basic Principles Of Durma Equipment Toronto

Water is a regularly made use of coolant, frequently flowed with a warm transfer or refrigerator system. One instance of water cooled laser handling is a laser microjet system, which pairs a pulsed laser light beam with a low-pressure water jet to guide the beam in the very same manner as an optical fibre.

Fibre lasers are also obtaining appeal in the steel cutting industry. This innovation utilizes a strong gain medium instead than a fluid or gas. The laser is intensified in a glass fiber to generate a far smaller spot dimension than that accomplished with CO2 techniques, making it optimal for cutting reflective metals.

Durma Press Brakes Toronto Fundamentals Explained

Plasma cutting which is a thermal cutting technique, is commonly made use of to reduce or inscribe on products such as steels. This is one of the fastest cutting methods readily available that ensures high-quality and precise cuts without triggering any type of wear and tear on the material. Although being a preferred metal reducing technique, many of us are not aware of plasma cutting.

Therefore, plasma cutters can pass with metals such as brass, aluminum, steel, and also copper without any resistance. A Plasma Reducing Device operates by utilizing ionized gas (plasma) to puncture conductive materials. It involves a power supply, gas circulation, plasma generation, a plasma torch, and also the cutting process (durma press brakes toronto).

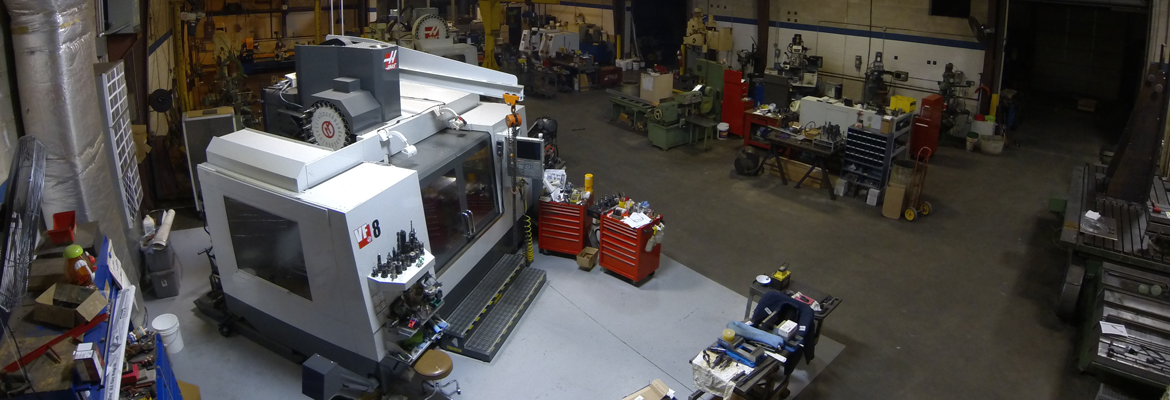

The firm is a leading supplier of sheet metal manufacture tools and equipment.

Excitement About Durma Press Brakes Toronto

Key aim of manufacturing is to transform raw or scrap product to beneficial item. There exist different kinds of manufacturing processes to meet such requirement. At some point the raw or scrap product is melted as well as poured into a premade dental caries to get that perception and this procedure is referred to as casting.

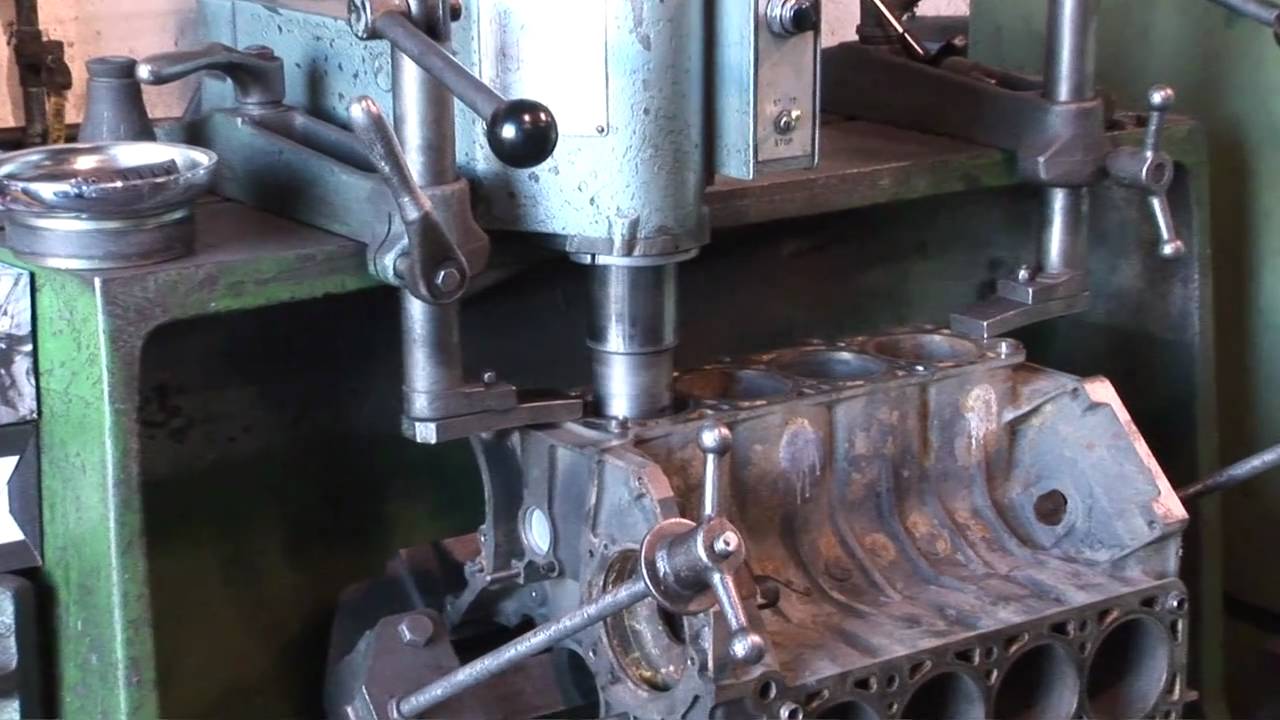

In creating, raw product is developed right into a particular form based on the requirement click site by applying outside pressure. All these processes specifically casting, creating as well as signing up with are generally one type of manufacturing process. Machining is an additional such instance where product is gotten rid of from the task by reducing (shearing) to get desired object.

Incidentally, bulk of design applications are based upon steels, so the alternative name is fairly rewarding. Traditional machining procedure is schematically received above figure. The figure is attracted on Orthogonal Aircraft, and also hence the suffix 'O'. It has to be kept in mind that the uncut chip thickness (a1) is constantly minimal than chip density (a2).

The 10-Second Trick For Laser Cutting Toronto

Therefore machining is likewise called a websites Subtractive Manufacturing Process. In comparison, quick prototyping is one kind of Additive Production Refine. Find out more: Additive as well as subtractive manufacturing processes. Machining is not just applicable for 'Steels', instead any kind of product can be machined. Steel is one type of material, the other 2 are Polymer as well as Ceramic.

Remember, in machining, product is basically gotten rid of by shearing. The cutting device compresses the product ahead it, there exists no pure compressive or tensile activity in removal of chip.

Consequently, plasma cutters can go through metals such as brass, light weight aluminum, steel, as well as copper without resistance. A Plasma Cutting Equipment operates by utilizing ionized gas (plasma) to puncture conductive materials. It entails a power supply, gas flow, plasma generation, a plasma lantern, and the cutting procedure.

Facts About Durma Press Brakes Toronto Revealed

The firm is a leading company of sheet steel construction tools and also equipment.

In creating, raw product is developed into a certain shape as per the demand by applying exterior pressure. All these processes particularly casting, developing and signing up with are primarily one sort of producing procedure. Machining is an additional such example where material is gotten rid of from the task by reducing (shearing) to acquire desired things.

The Buzz on Durma Fiber Laser

By the means, majority of design applications are based on metals, so the alternative name is rather satisfying. Traditional machining process is schematically revealed in above figure.

Machining is not just appropriate for 'Steels', rather any kind of material can be machined. Steel is one kind of material, the other 2 are Polymer as well as Ceramic.

Bear in mind, in machining, product is essentially removed by shearing. The cutting device presses the product in advance it, there exists no pure compressive or tensile action in elimination of chip.